4D printing – by Matthew Young

Hallo everyone and welcome back to another feature Friday. We have been offline for a few weeks but are really excited about this weeks post. It is guest post by Boston based freelance writer and blogger Matthew Young. Here he tells us about the exciting developments in 4D printing.

Thirty years after its birth, 3D printing has become commonplace in manufacturing and household settings. Also known as additive manufacturing, 3D technology has become affordable for almost any application. Consumers can now buy 3D printers for less than $1,000, opening the doors to entrepreneurs who can create custom products on demand. Now, manufacturers and healthcare practices use the new technology to create custom solutions for problems they once thought were impossible to solve.

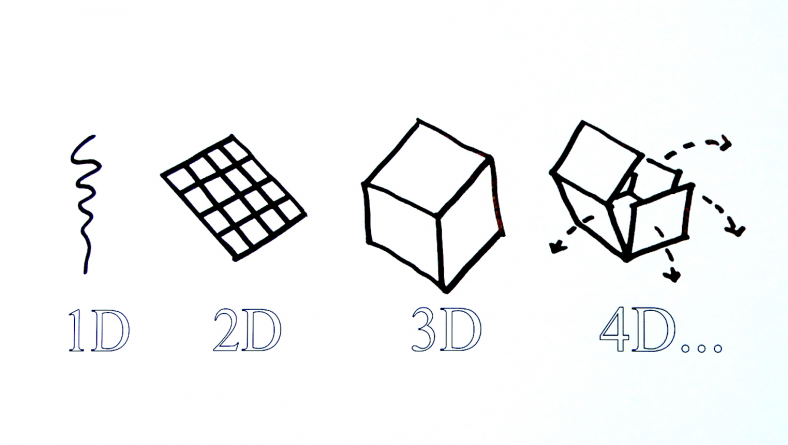

Although 3D printing has become entrenched in the business world, news of a new dimension has emerged, confirming that no one can slow technological innovation. Improvements to 3D printed materials have made them more versatile than they once were. Printers can now pre-program structures to transform themselves in response to stimuli. Scientists have dubbed the new technology “4D printing” to differentiate printer outputs that change with time and their environment from ordinary 3D printouts.

What is 4D Printing

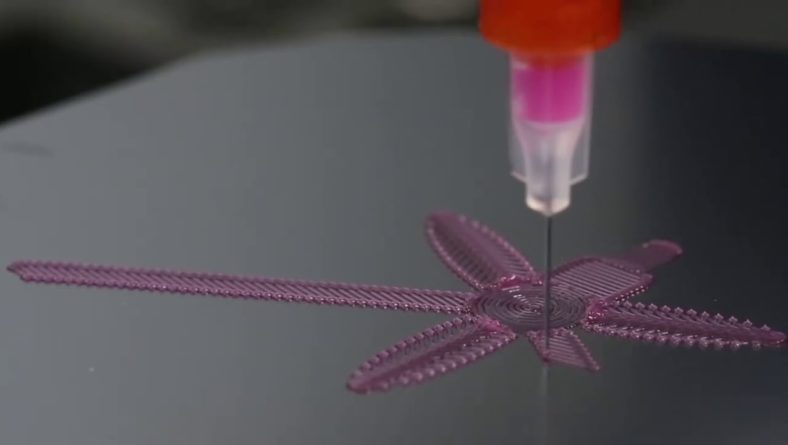

A collaborative effort by researchers from multiple organizations developed 4D printing as a way to print customizable smart materials. Companies including Stratasys and Autodesk developed the new process that adds the ability to transform shapes from one form to another directly from the printing environment. Fully functional objects can have properties that include sensing and actuation without the complicated devices and mechanisms that currently characterize robotics. Such transformational capabilities promise to revolutionize the many industries that can benefit from objects that adapt their environment including robotics and clothing. 4D objects can respond to numerous stimuli including temperature and moisture. They can also react to light and simple charges of energy.

Self-Assembly Lab

Skylar Tibbits, an MIT researcher, joined forces with counterparts from the business world to develop a way to print objects that can change their geometric form. Using a so-called Self-Assembly Lab, Tibbits discovered ways to make fluid objects without embedding them with sensors and motors. The successful research has made smart objects a reality. Tibbits sees the new technology as a way to revolutionize nanotechnology as well as sports shoes and attire.

Wyss Institute for Biologically Inspired Engineering

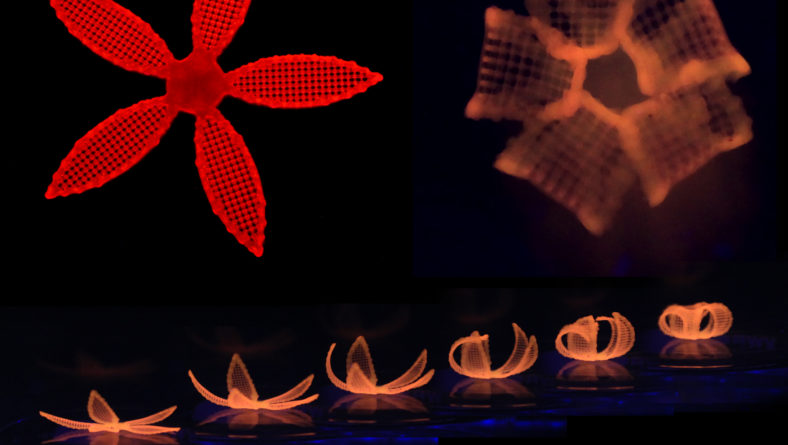

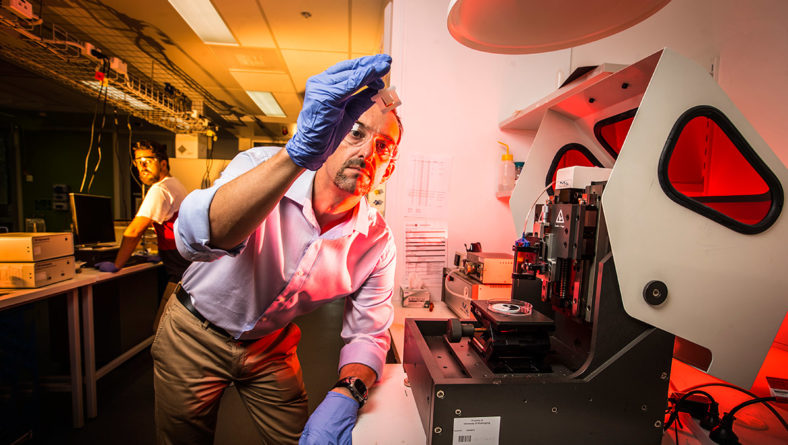

Another form of 4D printing seeks to emulate the way plants transform throughout their lifespan. Scientists at Harvard’s Wyss Institute for Biologically Inspired Engineering have teamed with Harvard John A. Paulson School of Engineering and Applied Sciences to develop 4D technology that responds to water and the passage of time.

Using a new hydrogel ink that contains cellulose fibrils, scientists have created objects that can morph during as they absorb moisture. The technology has the potential to pave the way for smart clothing and soft electronics. Researchers also see the reactive 4D printouts to have applications in the fields of biomedical and tissue engineering.

University of Wollongong

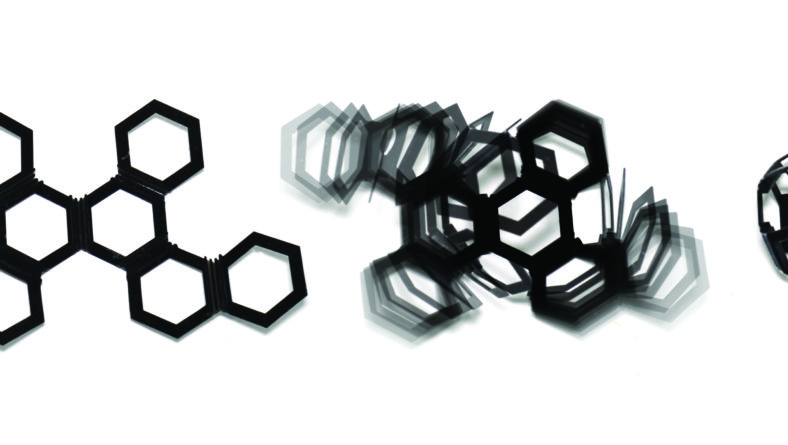

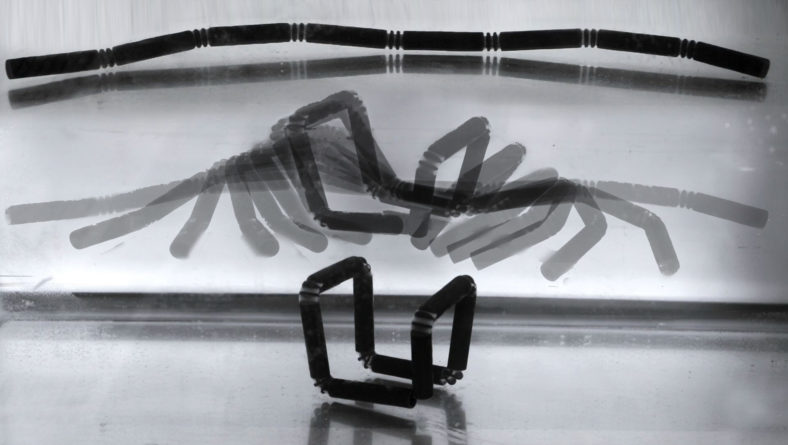

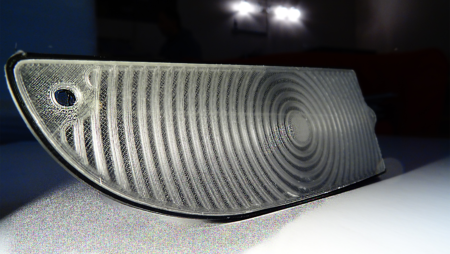

Australian researchers have also made progress with 4D printing technology. A team from the University of Wollongong have developed a way to print objects that respond to pressure and temperature, as well as water, that can revert to their original shape, if necessary. Efforts have produced self-assembling bodies powered by smart nanostructure strands. The objects open and close on their own without straining the material, suggesting that companies could soon create products that never wear out.

The ability of the material developed by the Australians can quickly transform construction in dangerous environments by eliminating the need for humans or robots. Printers could encode entire buildings into small smart objects which could unfold when placed in their intended environment. The researchers also expect their technology to get smaller and soon revolutionize molecular medicine.

3D printing changed the way people think about “printouts.” Now, 4D technology promises to change the way we think about mechanical objects by making complicated mechanisms practical on the molecular and macro scales. The ability to make objects that transform in response to stimuli over time will help companies make products that adapt to individual consumers and create mechanical objects with fewer moving parts. 4D technology also has significant implications for space exploration, by making unattended construction possible.

About the Author:

Matthew Young is a freelance tech journalist and blogger hailing from Boston. He is passionate about new, emerging tech in the industry. When Matthew is not busy writing about awesome new technology, he usually spends time fiddling with his camera and learning a thing or two about photography. You can reach Matthew on Twitter @mattbeardyoung!

Reference image credits:

ARC Centre of Excellence for Electromaterials Science University of Wollongong

No Comment

You can post first response comment.