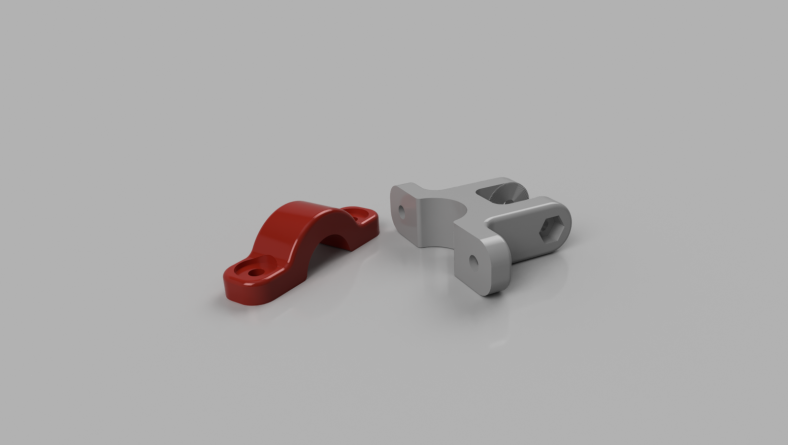

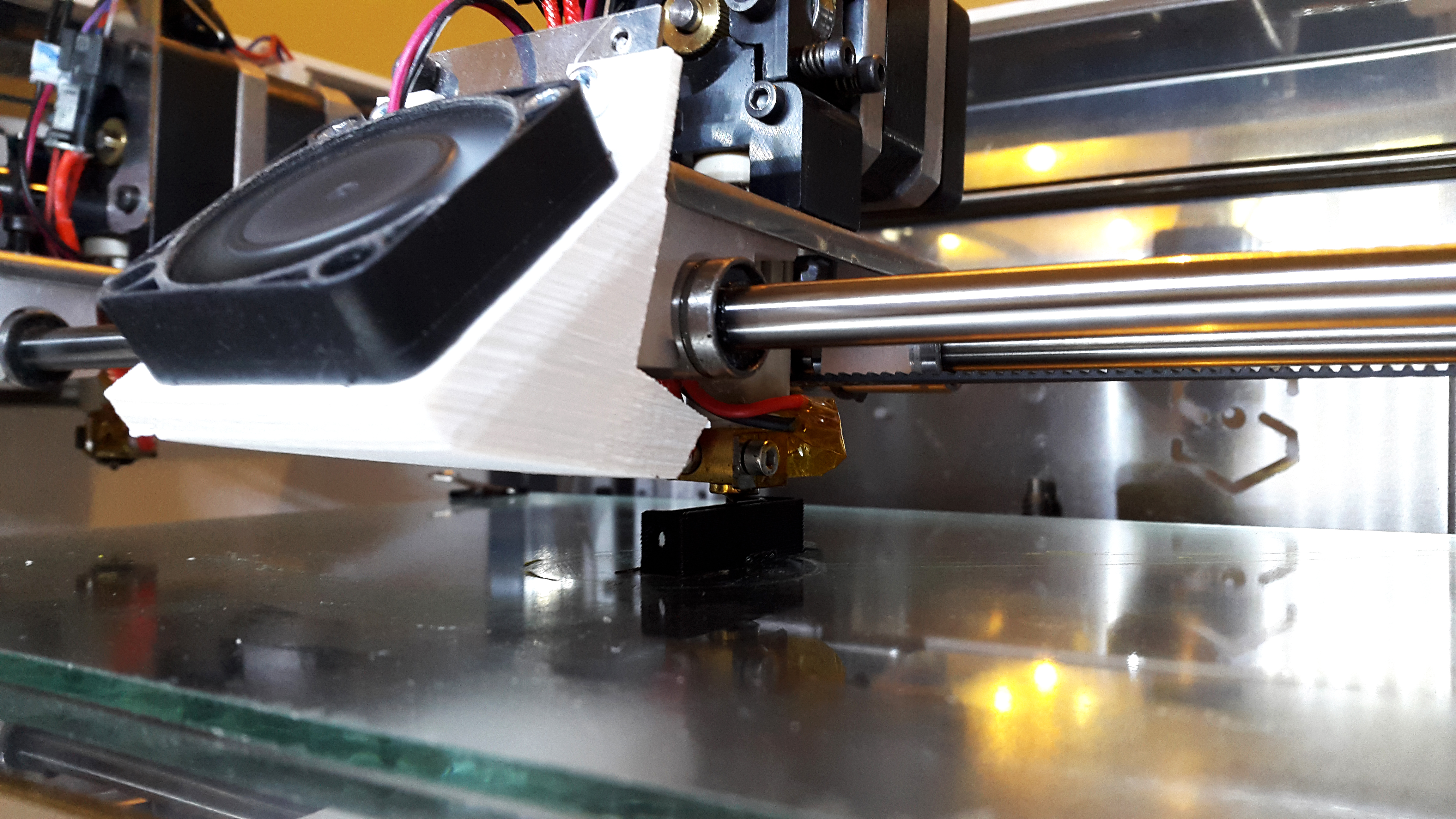

Custom made rear mudguard bracket

The 3D printer in its present form offers endless possibilities for the realization of all imaginable objects and models. The broad spectrum of possibilities attracts many users to 3D printing technology with their creative challenges often fueled by a simple need.

Creative energies in motion

Sometimes, and for some, inspiration comes naturally. The utter discomfort of wet pants caused by tyre splash back on the bike ride to the work was enough to motivate product designer Pelgrim Vandererkhoven. Two days ago the bracket for his rear mudguard failed. Typically, it rained non-stop over the next few days. The design team of the design and 3D printing office “DimensionAlley” at Liselotte Herrmann Strasse in Berlin could not, however, sit still, in their wet pants, without fixing the problem! Within a few hours, a new version was created in the form of a CAD file which was immediately exported as an STL and printed from PLA plastic.

Practical use

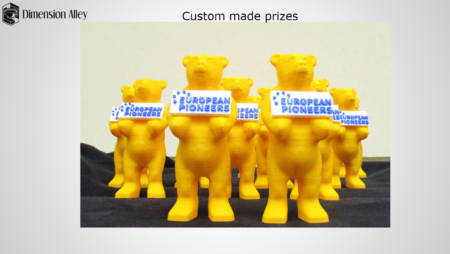

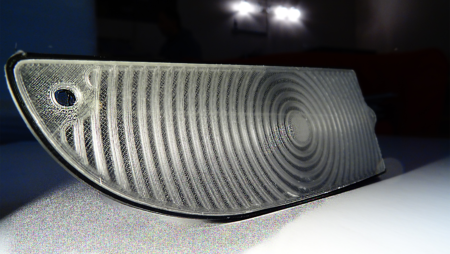

The new version is a lot more accurate in the print production than it would need for practical use, is more stable and fits better than its predecessor. In less than two hours, the idea became a directly applicable reality. This example is just one in a hundred, from car headlight bulbs, eyeglass holders, eyewear, furniture parts, IT technology panels, drone propellers, and model airplane parts that the design team at DimensionAlley has materialised from an idea!

No Comment