Why do you need 3D printing soon?

Guest post by Sachidanand Shetty, business development intern at DimensionAlley

If time and money is a priority for your business, then 3D Printing could play and important role in your strategy. Here are the five reasons why we believe you need to incorporate 3D printing technology in your business today.

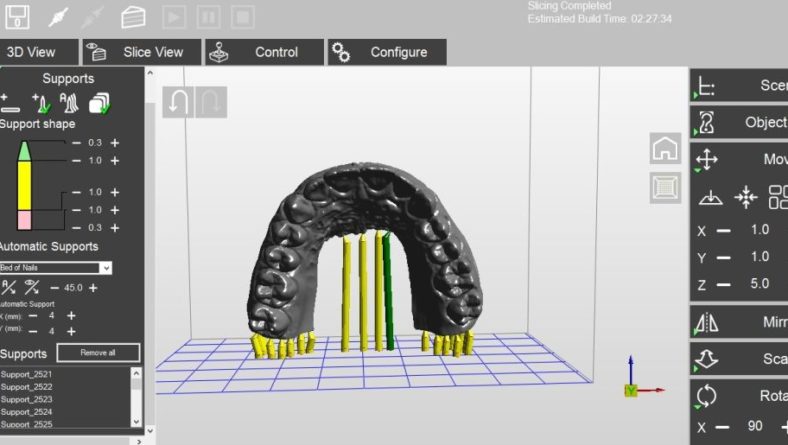

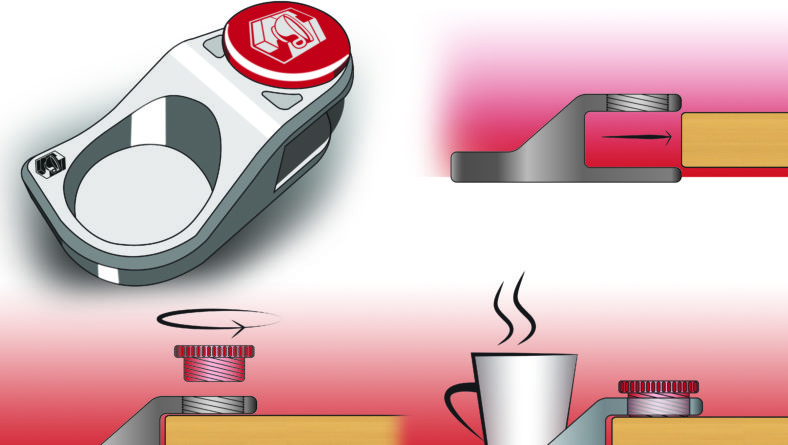

1. Design and Prototyping

Leave behind the costs incurred for multiple moulds and expensive tooling and see your idea prototyped rapidly. Unlike the expensive traditional way of prototyping use a 3D printer to make changes in your product ideas in a few clicks, change your digital model and print it. Many complex objects can be printed in one piece thereby eliminating the stress of producing several parts and assembling them together. You can model holes and screw threads directly into the object for precision and saving on hand work.

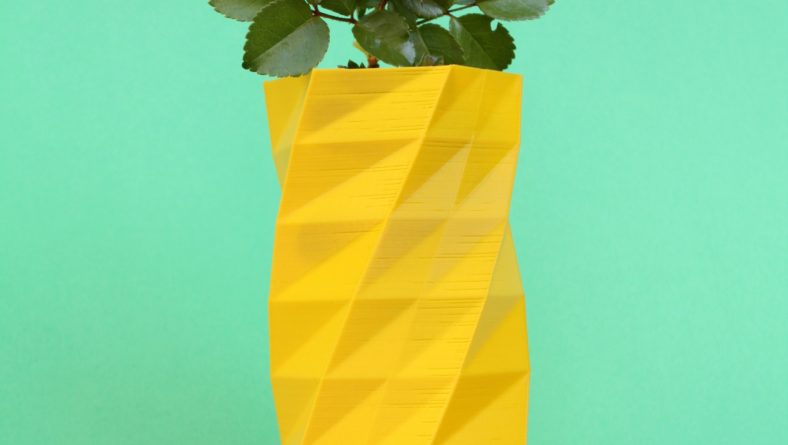

2. Complexity

The craftsman is less dependant on his skill with tools so that the imagination is more of a limitation than the production. Sharebot 3D printers can bring a complicated design into a reality. This feature makes the technology an ideal alternative for industries making customized products and multiple prototypes.

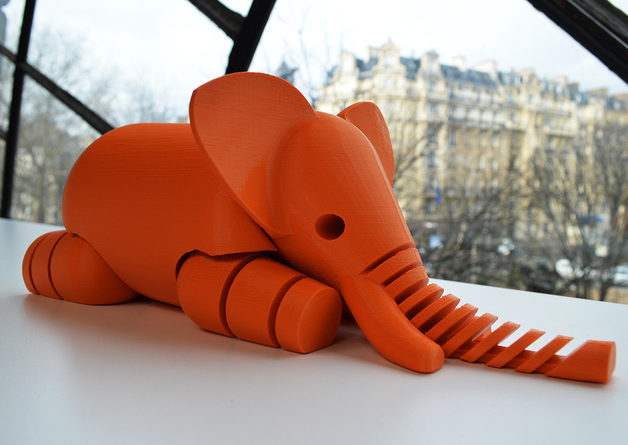

3. Eliminate Waste

Casting, cutting, milling, forging and polishing all produce significant waste. A well designed digital models can be printed with minimal to 0% waste. Turnaround the process using the 3D printing technology. One example which shows this brilliantly in the Elephant from Le Fab Shop, perfectly designed for FDM printing with no waste or supports or infill but fully movable.

4. Alternate Materials

3D Printing gives space for the use of materials which cannot be used in traditional prototyping and manufacturing. Plastics and Photosensitive resins and metals are very popular materials. Also, the list of printable materials is increasing to includes ceramic, cement, glass, numerous metals and metal alloys, compostable filaments, memory foams, felt like….the list of new and experimental materials goes on. This is removing a significant barrier to 3D printing as the list of printable materials grows.

5. Be a part of revolution

,

3D printing is changing the traditional methodology of prototyping and manufacturing. In a recent survey by PWC of 100 companies, 11 percent of them had already shifted to the production of 3d printed parts and according to analysts the technology is mainstream if it reaches the acceptance level of 20 percent. The technology advances day-by-day and finding its way to new sectors. The success stories such as the United States hearing aid industry completely shifting towards 3D printing in less than 2 years is pumping confidence for different sectors and industries to incorporate the technology. This revolution doesn’t belong to a few. With the desktop 3D printer getting cheaper and various companies providing software to build 3D models, you have every reason to join the 3D printing revolution

Reference

No Comment